WhatsApp)

WhatsApp)

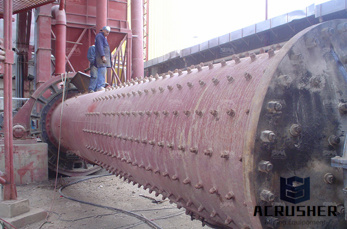

Ball Mill. Group No. 3 LOGO Contents Introduction Types and Process Principle of work Description of Ball mill Design and Cost Introduction

Design Safer Chemicals ... What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 .

hydrocyclone roller mill design,best design mineral agitation tank machine plant for sale,design of chrome grinder plant,single toggle flotation cell plate design ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary ... An important characteristic of an industrial ball mill is its ...

What is a Ball Mill? ... and it is important to make sure that current maintenance keeps pace with current technology and machinery design. Ball mill ... FAB 3R. All ...

This ball mill was made from a design by Lloyd Sponenburgh. It''s a very efficient ball mill and each 1 gallon jar can mill 1Kg of black powder in 3 hours.

Ball Mill Free download as PDF File (.pdf), Text File (.txt) Ball Charge Design. Ball Charge Design. by Vishnu Vardhan . C. ballmill. ballmill. by Taufik Achmad.

Ball Mill, Ball Mill Design Procedure. Ball Mill. Ball mil is a type of grinder used to grind materials into extremely fine powder. According to the need of customers ...

Notes on Ball Mill Design Power Draw. Power Draw is steady running power requirement ... ignoring drivetrain losses and startup loads. Power Draw is reduced for ...

Browser Tool for Ball Mill Design Power Draw. Control: Ball Mill Design Power Draw: Tool Parameters Values displayed with a may be changed ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

The design of a two flute ball end mill allows for plenty of chip evacuation making them most effective in contouring deep pockets in molds and dies.

ball mill grinding media calculation – Grinding Mill China. Posted at: August 1, 2012. Ball mil design calculation? – Yoo! Answers Apr 01, 2008 · Ball mil ...

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

Video embedded· Make a Ball Mill in ... I haven''t found a suitable motor to drive my ball mill, ... how to make a ball mill with lego and a pvc pipe includes digital design .

How to Make a Ball Mill. Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument ...

FL ball mill for cement grinding. Versatile system based on standard modules 2 The FL ball mill is designed for ... Proven mill design 6

Quickly find the top 5 ball mill manufacturers. Wide range of products, best deals, custom solutons, superior strength, demanding applications, low cost.

Building a Ball Mill ... I will NOT be held responsible for any misuse of this design, intentional or unintentional, resulting in loss of fingers, toes, ...

PATTERSON''s unmatched Ball and Pebble Mill custom design experience and manufacturing ... PATTERSON Batchtype Ball Pebble Mills. ... Ball Mill without ...

Ball Mill. 140 likes. Ball mill for grinding various ores and other materials, are widely used in mineral processing, building materials and chemical...

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

The present work aims to design and analysis of Ball mill inlet chute along with the truck assembly for Roller press circuit UMS (Unidan Mill S) ...

WhatsApp)

WhatsApp)