WhatsApp)

WhatsApp)

Kinetic Reduction of Mill Scale via Hydrogen ... and it is suiTab. for direct recycling to the blast furnace ... The reduction of mill scale by hydrogen was done in a ...

Journal of Metallurgy is a to occur which retarded the direct reduction of mill scale, reduction of mill scale waste produced in . direct reduction of mill scale ...

The MIDREX MEGAMOD Direct Reduced Iron facility is by far the most advanced plant to produce simultaneous both high quality cold (CDRI) hot direct reduction iron ...

An overview of utilization of slag and sludge from steel industries. ... The reduction of oily mill scale sludge along ... MensingerRecovery of direct reduced ...

Direct Reduced Iron ... the small scale of DRI operations also act as a barrier for ... the heat from the direct reduction process lowers the cost of melting ...

Utilization of Low Grade Coal for Direct . In this paper an attempt has been made to utilize the low grade coal for direct reduction of mill scale in laboratory to ...

P reparation of iron Powder s by Reduction of Rolling Mill Scale Said Mechachti 1, Omar Benchiheub 1, ... such as the blast furnace or the direct reduction reactors

O. Yucel et al., Determination of Direct Reduction Conditions of Mill Scale 407 shown in Figure 3 and the chemical composition is given in Table 1.

Substitution of DRI for scrap can reduce mini mill''s reliance on scrap as a feedstock, ... first fullscale commercial deployment ... Direct Reduced Iron facility .

Direct Reduction Of Mill Scale. Get Price And Support. Motor controller Wikipedia, the free. A motor controller is a device or group of devices that serves to ...

Determination of Direct Reduction . Read "Determination of Direct Reduction Conditions of Mill Scale, High Temperature Materials and Processes" on .

IUCLID 5 COMPOSITION AND ANALYSIS GUIDANCE DOCUMENT: MILL SCALE ... Mill scale is composed mainly ... for the determination of metallic iron in direct reduced ...

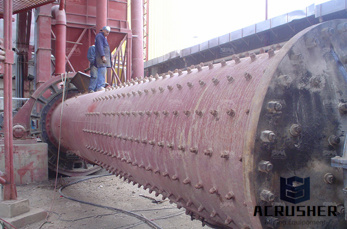

Apparatus for direct reduction of iron oxides. A method of and apparatus for reducing an oxide of iron such as the oxides which occur in mill scale involves mixing ...

Production of sponge iron powder by reduction of rolling mill scale . A study was made of the reduction of mill scale to sponge iron using coke at different ...

Rolling (metalworking) Wikipedia. The invention of the rolling mill in Europe may be attributed to Leonardo da Vinci in his drawings. The earliest rolling mills in ...

Elaboration of iron powder from mill scale O ... recycled by the metallurgical processes such as the blast furnace or the direct reduction reactors that uses ...

Directreduced iron (DRI), ... mill scale, furnace dust, etc.), in order to convert the ore to metallic iron, without melting it (below 1200 °C). ...

Dec 07, 2012· an investiga tion on the direct reduction of mill scale . an investiga tion on the direct reduction of mill scale from continuous steel casting ...

Mill scale is suitable for direct recycling to the blast furnace via sintering plant [4]. Ap ... The reduction of mill scale by hydrogen was done in a

Elaboration of iron powder from mill scale. Keywords: recycling, mill scale, reduction, carbon monoxide, iron powder. 1. such as the blast furnace or the direct ...

Production of sponge iron powder by reduction of rolling mill scale ... mill scale is suitable for direct recycling to ... asreceived and reduced mill scale ...

Mill scale is one of waste materials which is produced as a result of hot rolling of steel in all steel companies. On the other hand, mill scale is considered a rich ...

Substitution of DRI for scrap can reduce mini mill''s reliance on scrap as a feedstock, ... first fullscale commercial deployment ... Direct Reduced Iron facility .

direct reduction of mill scale. Elaboration of iron powder from mill scale direct reduction of mill scale,Abstract This work refers to the study of the conditions ...

WhatsApp)

WhatsApp)