WhatsApp)

WhatsApp)

why is the clinker grind down to fine powder for cement. ... ... Cement Clinker Grinding... to be able to reduce large return again ball grinding powder.

... over 150 countries produce cement and/or clinker, ... mineral inputs are reduced to ... the clinker nodules are ground into a superfine powder in a horizontal ...

Then you need to crush it to a fine powder. Then you need to heat it to volcanic temperatures until it forms nodules of cement ''clinker''. Finally, you need to grind the cement clinker back to a fine powder, add a bit of gypsum to control setting times, and hey presto you have that well known grey powder called cement!

A proactive partner in sustainability ... the Cement Association of Canada has registered Environmental Product ... Cement is a fine grey powder that is mixed ...

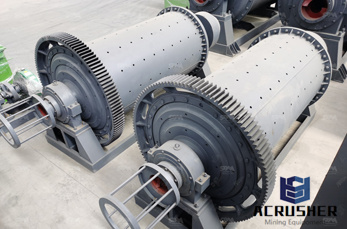

The term clinker is used to refer to lump cement. These clinkers are then fed to a large ball mill and reduced to 200 mesh ( a fine powder), ...

Portland cement is obtained through mixing of gypsum with an intermediate product of the cement production line called ''clinker''. This material is produced in the ...

Portland cement clinker ... The nodules are ground up to a fine powder to produce cement, with a small amount of gypsum added to control the setting properties.

Dec 09, 2016· The material formed in the kiln is described as "clinker" and is typically composed of rounded nodules between 1 mm and 25 mm across. After cooling, the clinker may be stroked temporarily in a clinker store, or it may pass directly to the cement mill. The cement mill grind the clinker to fine powder.

Materials Cheat Sheet 2 ... PORTLAND CEMENT named for limestone and chalk cliffs. ... clinker and pulverize to fine powder ...

Crusher Clinker Fine [ 9725 Ratings ] The Gulin ... cement clinker is reduced to fine powder by. cement clinker is reduced to fine powder by australia ...

A study on development of recycled cement made from waste cementitious powder. ... cement with no fine ... clinker), the carbon emissions were reduced to ...

cement clinker is reduced to fine powder by. feed back cement,the free encyclopedia cement is often supplied as a powder,which is mixed with other materials and water ...

... to 10 volume percent interground fiber in hydratable cement powder is prepared by ... the mixture until the clinker has been reduced to a fine powder.

Cement Wikipedia. Cement is used with fine dry cement powder in In the European union the specific energy consumption for the production of cement clinker has been ...

Grinding Clinker 1500x6000mm. ... cement clinker is reduced to fine powder by cement clinker isGet ...

The cement manufacturing process starts from the mining of ... Cement clinker is made by ... The ball mill grinds the feed to a fine powder in ...

How cement is made and history of ... a rocklike substance that is ground into the fine powder that we commonly ... to form a new substance called clinker.

manufacturing and use of cement can be reduced by up to 70%. ... into a fine powder. The powder, ... Cement clinker in less efficient, ...

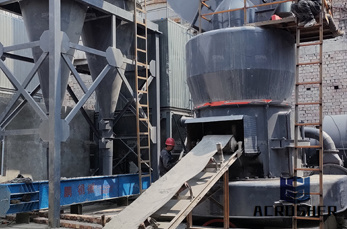

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc.

cement clinker powder grinding. feb contact us for help http cement clinker is reduced to fine powder by cement ...

... the mixture until the clinker has been reduced to a fine powder. The ... fiber in hydratable cement powder is prepared by introducing ...

Patent USInterground fiber cementGoogle . the mixture until the clinker has been reduced to a fine powder. The fiber in hydratable cement powder is prepared by ...

A primary ingredient of cement – clinker ... That mixture is milled to a fine powder (cement). ... the specific energy to produce a unitmass of cement is reduced ...

The reduced clinkers contain ... the clinker or cement to react with the reagent by treating ... Grind an OPC clinker nodule to a fine powder using a porcelain or ...

WhatsApp)

WhatsApp)