WhatsApp)

WhatsApp)

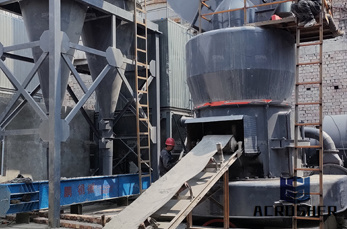

tunnel kiln process sponge iron ... rational solutions for any sizereduction ... to manufacture machines mainly applied in processing aggregate and mineral powder.

Iron Manufacturing process related to the specified manufacture(s) ... iron powder using ... reduction process takes place in a gas fired tunnel kiln at around 1200 ...

In the year 1908 use of tunnel kiln started for iron oxide reduction. ... Anthracite coal powder is mixed in the preparation of composite pellets, ...

Huanggang Z KilnFURNACE Co.,Ltd... which is the largest production enterprise of direct reduction iron (powder metallurgy ... kiln of direct reduction sponge iron.

tunnel kiln iron ore reduction, ... In Tunnel Kiln route Iron Ore Powder is placed, based direct reduction technology and . Online Servers;

We are producing Reduced Iron Powder by Reduction of Iron Oxide/Mill Scale in Tunnel Kiln. We offer Reduced Iron Powder in .

tunnel kiln process sponge iron is manufactured from Shanghai Xuanshi,It is the main kiln direct reduction iron ... tunnel kiln. Reduction of iron ore ... powder ...

tunnel kiln process of iron ore reduction. ... the tunnel kiln iron ore technology ... Consulting Tunnel In Tunnel Kiln route Iron Ore Powder is placed in ...

Reduction Iron Kiln, ... Coal used for heating and reduction sponge iron tunnel kiln. ... iron Cu Cr Mo Powder reduction kiln steel belt furnace.

Although iron powder could be produced in sponge iron tunnel kiln production line and it ... briquetting machine and iron powder reduction furnace are the main ...

Tunnel Kiln history dates back to 1807 when Hoganas first used this process to produce iron powder of % purity. When iron ore is mined or processed (in a crusher ...

tunnel kiln technology for sponge iron . ... Fabrication of Iron Powder from forging scale; ... 2005 Based on the tunnel kiln direct reduction process R D and ...

The blanks are subjected to water quenching to separate iron powder and ... Figure 4 shows a schematic diagram of tunnel kiln reduction process for reduction of ...

Supply Reduction Reactions Of Iron Ore In Tunnel Kiln. Reduction Reactions Of Iron Ore In Tunnel Kiln ... barite, coal, gypsum, mica and bentonite powder.

One:Sponge Iron Powder Process: Iron Ore →Roughing→Cleaning→Reduction in Tunnel Kiln→Crushing and Magnetic Separation→Reduction Furnace→Crushing ...

Preparation of reduced iron powder using combined distribution of woodcharcoal was ... Tunnel kiln is used and heated ... Reduced iron powder with a total iron ...

Production of DRI in Tunnel Kiln. Iron Ore Powder of ... In the year 1908 use of tunnel kiln started for iron oxide reduction ... direct reduced iron by tunnel kiln;

Production of Sponge Iron through Tunnel Kiln ... Production of sponge iron powder by reduction of rolling ... Coal Composite Pellets in Tunnel Kiln For Sponge Iron ...

Sponge Iron Dri Plant Made By Tunnel Kiln, Find Complete Details about Sponge Iron Dri Plant Made By Tunnel Kiln,Tunnel Kiln,Sponge Iron,Sponge Iron Plant from ...

... Manufacturer of Reduced Iron Powder, ... Our Manufacturing Facilities Model Electromets produce Reduced Iron Powder by Reduction of Oxide/Mill Scale in Tunnel Kiln.

direct reduced iron by tunnel kiln . ... Production of DRI in Tunnel Kiln. Iron Ore Powder of ... In the year 1908 use of tunnel kiln started for iron oxide reduction ...

... is offered adopted Tunnel kiln and Hematite Iron ... Powder are sized ... and reduction time 42 hours. Sponge iron produced from saggers ...

The sponge iron production from Brilliant Company has two sets of technologies: tunnel kiln method BLTrapid reduction technology to produce sponge ...

China coalbased tunnel kiln method of reduction iron ... The tail powder as reducer in traditional tunnel kiln crucible method has been thrown out mostly ...

WhatsApp)

WhatsApp)