WhatsApp)

WhatsApp)

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = rpm.

effect of operational variables on ball milling Poli Monografias UFRJ prove of critical speed equtaion in ball mill,Ball mills have large applicability in the ...

Ball Mills Mine provides mining, gold, copper, coal ... information on ball mills ... This formula calculates the critical speed of any ball mill.

tumbling mill critical speed. aug i am going to discuss only one more variable that has to do with grinding media and that is critical speed of tumbling ...

» formula for critical speed ball mill is derived from » formula to calculate critical speed in ball mill » critical speed calculation formula of ball mill .

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

How did you derived the formula for the critical speed of the ball mill?

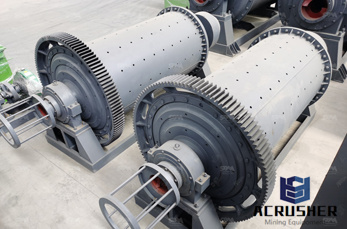

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Original document English (PDF 367kb) ,ABSTRACT: In this study, the effects of ball charge, powder filling, mill speed and while it asymptotically increased ...

Critical Speed of Ball Mill For a ball mill, it does not have a constant critical speed, because of the centrifugalization of the steel balls is different accor

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, ... The theoretical critical speed of a ball mill is the speed at which the centrifugal force is

A ball mill is a type of grinder used to grind and blend materials for use in mineral ... Critical speed can be understood as that speed after which the ...

Ball Mill Operating Speed Mechanical Operations . The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm ...

formula for calculating the critical speed of a . calculator for ball mill critical speed Grinding Mill China. calculator for ball mill critical speed ... for ...

Derivation of critical speed of grinding mill – The QA wiki. What is critical speed of a SAG mill? The critical . is two latticetype ball mill. The materials ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... The critical speed of the mill, ... is defined as the speed at which a single ball will just remain against the wall ...

Jun 19, 2015· https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill .

Cement mill notebook SlideShare. Jan 7, 2015 Raw mills usually operate at 7274% critical speed and cement mills at Calculation of the Critical Mill Speed: G ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

The Critical Speed is used for the determination of ball mill ideal operating speed. But for comparison, rod mills would operate between 50% to 95% of the critical speed.

Critical Speed of Ball Mill Critical Speed of Ball Mill For a ball mill, it does not have a constant critical speed, because of the ...

Particle size reduction of materials in a ball mill with the presence of metallic balls or ... Cylinder speed (60% critical) HP (Wet ... Lined Ball Mills. Model ...

formula for critical speed of ball mill vertical shaft impact, Simulation studies on Energy Requirement, Work Input and, IJETAE number of balls, time of ...

WhatsApp)

WhatsApp)