WhatsApp)

WhatsApp)

Every coal pulverizer is designed with a particular fuel grinding capacity or throughput at a certain Hardgrove grindability index (HGI), based on a defined raw coal ...

Reliable coal pulverizer performance is essential for sustained fullload operation of today''s power plants. An effective pulverizer must be capable of handling a ...

Here you will find listings of coal pulverizer, coal pulverizer manufacturers, coal pulverizer suppliers, coal pulverizer exporters and manufacturing companies from ...

Coal Pulverising in Boilers. ... In the suction type, the exhauster is used for lifting the milled coal from the pulverizer to the furnace through a cyclone.

Improving Coal Pulverizer Performance and Reliability. A p p l i c a t i o n U p d a t e Introduction Power generation industry studies have shown that coal ...

Reports of 26 coal pulverizer fires and explosions are reviewed in order to elucidate causes and preventive measures. Most of the explosions occurred during ...

Columbia Steel casts replacement wear parts for MPS 89, MPS 89G, MPS 89R coal pulverizers, including wear tires, roll brackets, wear track segments, more.

Find here details of companies selling Coal Pulverizer, for your purchase requirements. Get latest info on Coal Pulverizer, suppliers, manufacturers, wholesalers ...

STORM TECHNOLOGIES, INC. April 2011 Pulverizers 101: Part 1 The Storm Approach to Coal Pulverizer Optimization IN THIS ISSUE: What is pulverizer capacity?

Introduction. Power generation industry studies have shown that coal pulverizers are an area where improved equipment reliability is badly needed.

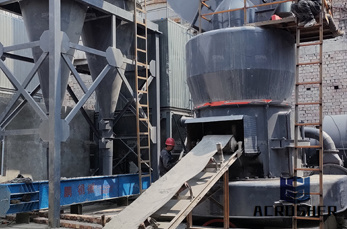

Coal Pulverizer, Coal Pulverizer Mill, Coal Mill Pulverizers. Machinery is a manufacturer of coal pulverizing equipment. The four most common types of coal ...

Feb 23, 2010· Video embedded· Unsubscribe from Williams Patent Crusher and Pulverizer Co., Inc.? Here''s a 3D animation of how a coal grinding system works. Williams Crusher has the ...

combustion engineering coal pulverizer design. CFD appliion for coal/air balancing in power plants. Several coal pipes connect the exit of the pulverizer to the ...

Application Update Introduction Power generation industry studies have shown that coal pulverizers are an area where improved equipment reliability is

Holmes Model 500DG. Holmes Pulverizer Model 500DG has a capacity of 400 grams of coal per minute using a screen with " diameter perforations and is recommended ...

Experience you can trust ... RPM has successfully rebuilt over 1600 pulverizer rolls and 275 tables onsite since 1986!!! Our coal pulverizer maintenance program has ...

Coal Pulverizer''s are used to pulverize the coal into a fine powder of size around 80 microns in a pulverizer and this coal is then injected into boiler furn...

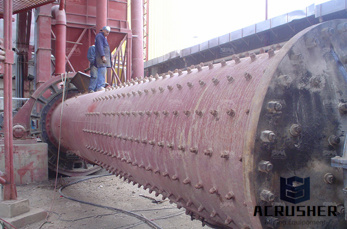

Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the ...

Manufacturer of Coal Pulverizer offered by Micro Pulverizer Manufacturing Works, Mumbai, Marashtra

These benchtype pulverizers are recommended for reducing coal or coke from to sieve size.

On a scheduled rotation, each coal pulverizer gearbox is prioritized for rehabilitation based on operating cycles and condition monitoring assessments.

So the next time you need to replace a coal pulverizer bearing, whether it''s from Messinger or another manufacturer, just contact us with your part number.

American Pulverizer Company designs and manufactures reduction equipment and complete shredding systems for scrap metal, coal, wood, and many other materials.

Coal Pulverizer, Wholesale Various High Quality Coal Pulverizer Products from Global Coal Pulverizer Suppliers and Coal Pulverizer Factory,Importer,Exporter at ...

WhatsApp)

WhatsApp)